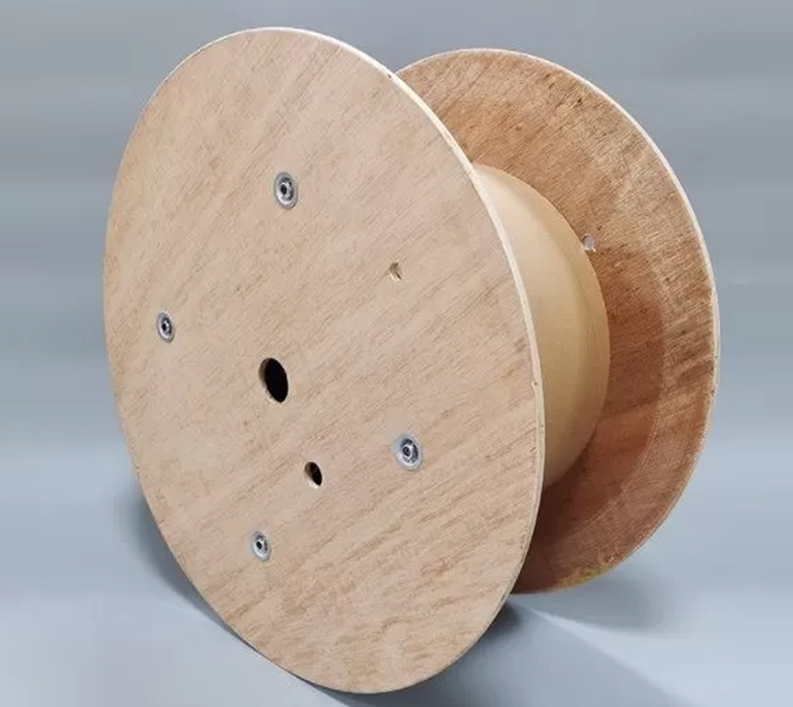

The engineered strength, stability, and weather-resistant core for durable cable reel flanges.

.."The engineered strength, stability, and weather-resistant core for durable cable reel flanges."

Circle plywood is a high-strength, stable, moisture-resistant engineered wood product precisely manuf.

actured into circular disks. Its exceptional structural properties, screw-holding ability, and dimensional stability make it the material of choice for the flanges of cable and wire reels worldwide, where it reliably contains, supports, and protects heavy cable loads during transport and handling.

※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※※

Standard Sizes (Typical):

✅Diameter:Ranges widely from 198mm up to 1300mm or even larger for custom reels. Common sizes include 600mm, 900mm, 1200mm, 1500mm, 1800mm.

✅Thickness: Varies significantly based on reel size and cable weight. Common thicknesses range from 15mm for smaller reels to 70mm or more for very large, heavy-duty reels.

✅Grades: Generally produced to industrial grades focused on structural integrity rather than surface appearance. Faces are typically sanded smooth.

Primary Use: Cable & Wire Reels (Drums)

✅Flanges: Circle plywood disks are the core component forming the two vertical flanges (sides/walls) of a cable or wire reel. They are bolted onto a central spool (drum), which can be made of steel, wood, or sometimes also thick plywood.

Function on the Reel:

✅Containment: Prevent the wound cable or wire from unspooling sideways.

✅Structural Support: Bear the immense radial forces generated by tightly wound, heavy cable coils. They transfer this load to the central drum and the reel's axle or lifting points.

✅Handling: Provide surfaces for attaching lifting eyes, rolling rims (often steel bands), and labels. Must withstand impacts from forklift tines and handling equipment.

✅Protection: Shield the cable edges from damage during transport, storage, and handling.

Why Plywood is Dominant for Cable Reel Flanges:

✅Strength-to-Weight Ratio: Plywood offers exceptional strength (especially birch) while being lighter than equivalent solid wood or steel flanges.

✅Cost-Effectiveness: More economical than solid hardwood or metal for many applications.

✅Stability: Highly resistant to splitting, warping, and checking compared to solid wood.

✅Manufacturability: Easier and more consistent to produce large, precise disks than from solid timber.

✅Screw Holding: Superior grip for bolts compared to particleboard or MDF.

✅Moisture Resistance: WBP glue provides necessary protection for outdoor storage/transport.