PP PLASTIC FACED PLYWOOD

Durable, Waterproof & Eco-Friendly Construction Solution

PP PLASTIC FACED PLYWOOD

Durable, Waterproof & Eco-Friendly Construction Solution

Product Specifications

Parameter | Details |

Thickness | 12mm / 15mm / 18mm / 21mm (Customizable) |

Size | 1220mm x 2440mm (Standard) or Custom Sizes |

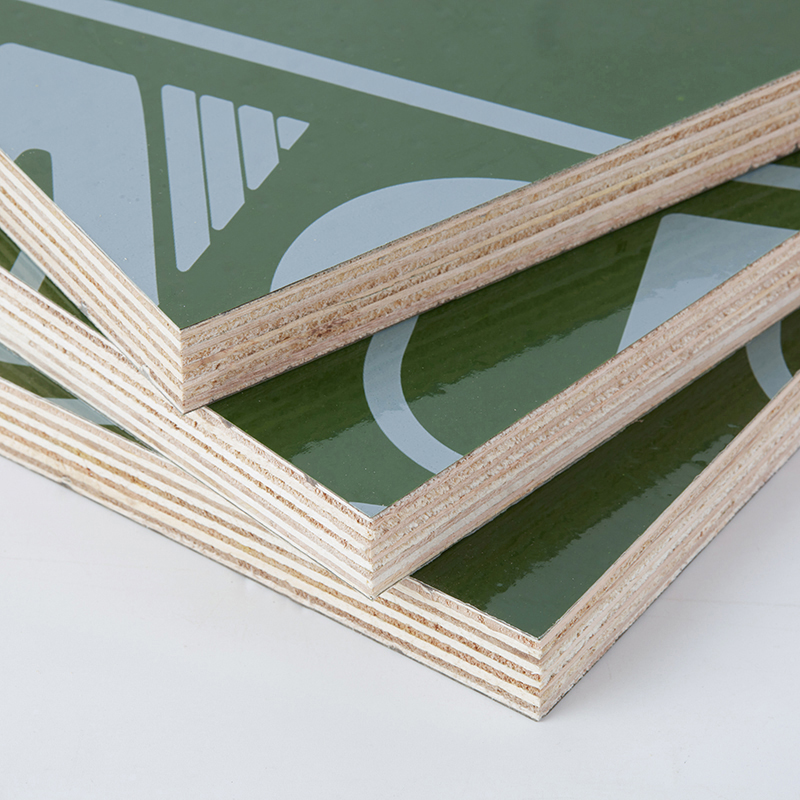

Surface Material | PP Film (0.4mm-0.5mm Thickness) |

Core Material | Birch/Poplar/Combi Plywood (Density ≥650kg/m³) |

Moisture Content | ≤10% |

Formaldehyde Emission | E0 Grade (CARB Phase 2 / ENF Certified) |

Surface Finish | Matte Anti-Slip Texture / Glossy or Custom Patterns Available |

Product Overview

Key Features:

Eco-Friendly: Surface-coated with green PP (Polypropylene) plastic film, formaldehyde-free, compliant with international environmental standards.

High Strength: Multi-layered hardwood core (birch/poplar) bonded with PP film for superior impact resistance and bending strength.

Waterproof & Moisture-Resistant: PP film seals the surface, ideal for high-humidity environments.

Weather Resistance: UV-resistant, anti-corrosion, suitable for indoor and outdoor use.

Easy Installation: Smooth surface ready for direct use or secondary processing (cutting, drilling).

Key Advantages

✅ Extended Lifespan: PP film enhances abrasion resistance, outperforming traditional plywood in reuse cycles.

✅ Lightweight Design: 30% lighter than metal templates, easy to handle.

✅ Sustainability: FSC®-certified, supporting eco-conscious construction practices.

Applications

Construction: Concrete pouring molds, temporary road plates.

Furniture Manufacturing: Cabinet backboards, table/chair bases.

Interior Decoration: Wall cladding, exhibition boards.

Logistics: Moisture-proof container flooring, heavy-duty crates.

Usage & Maintenance

Storage: Store flat in dry, ventilated areas; avoid direct sunlight.

Processing Tips: Use carbide-tipped blades for clean cuts.

Cleaning: Wipe with a damp cloth; avoid strong acids/alkalis.

Packaging & Delivery

Standard Packaging: Wooden pallets

Customization: Labeling, split packing upon request.

Global Shipping: Sea/land freight supported.

Certifications

CE Marking (EU Compliance)

FSC® Certification (Forest Stewardship Council)

CARB Phase 2 (Formaldehyde Emission Standard)

Unbeatable After-Sales Support

We stand behind our product with confidence:

✅ 12-Month Warranty: Coverage for manufacturing defects.

✅ 24/7 Technical Support: Expert guidance for installation or customization.

✅ Global Logistics: Reliable sea/land shipping with customizable packaging.

✅ Tailored Solutions: Need specific sizes, colors, or textures? We’ll make it happen.

Why Choose BLXING PP Faced Plywood?

✅ Save Time & Money

No Painting Needed: Skip costly surface treatments and jump straight to installation.

Reusable: Outlasts traditional plywood by 3x, slashing replacement costs.

✅ Eco-Conscious Performance

Zero Harmful Emissions: Formaldehyde-free and FSC-certified for sustainable sourcing.

Recyclable: PP film and wood core can be repurposed, reducing landfill waste.

✅ Versatile Applications

Construction: Perfect for concrete formwork, temporary flooring, and wall sheathing.

Industrial: Ideal for container flooring, machinery packaging, and heavy-duty crates.

Interiors: Use for sleek wall panels, exhibition boards, or furniture bases.